Starting a brick manufacturing business can be a smart move if you’re hunting for an opportunity with high demand, low investment, and a path to steady income. Bricks are everywhere—builders use them for homes, workplaces, schools, and more. The demand for bricks keeps growing thanks to rising populations, rapid urbanization, and an uptick in infrastructure development.

What’s even better? The brick making business is scalable, doesn’t require cutting-edge technology, and often pays off from the first month itself. If building a profitable, practical, and sustainable business is what you’d like, read on.

- High Demand: Needed in every construction project.

- Low Investment: Entry cost is manageable, with options for small and medium budgets.

- Steady Income: Ongoing demand leads to reliable cash flow.

- Scale Up Easily: Expand capacity as your business grows.

- Low Complexity: No need for advanced skills or technology.

Market Scope and Demand for Bricks

Bricks are the backbone of construction. India is the second largest brick producing country, right after China. No matter the project—homes, schools, offices, or factories—bricks are needed everywhere. The country is pushing urbanization, housing initiatives, and infrastructure projects like smart cities and affordable housing.

What’s Driving Brick Demand?

- Rapid urbanization.

- Rising population.

- Expanding housing projects.

- New infrastructure (roads, schools, offices).

- Government programs for affordable housing.

Fact: India’s brick market size is expected to reach $3.68 billion by 2030.

The year-round demand makes this a low-risk business. Most competition is local, so with the right planning, you don’t have to fight big national players. That means you build relationships with local contractors, builders, and architects.

If you want to explore more statistics and a detailed market outlook, the guide on how to start a brick factory and profit margin breakdown gives a comprehensive view.

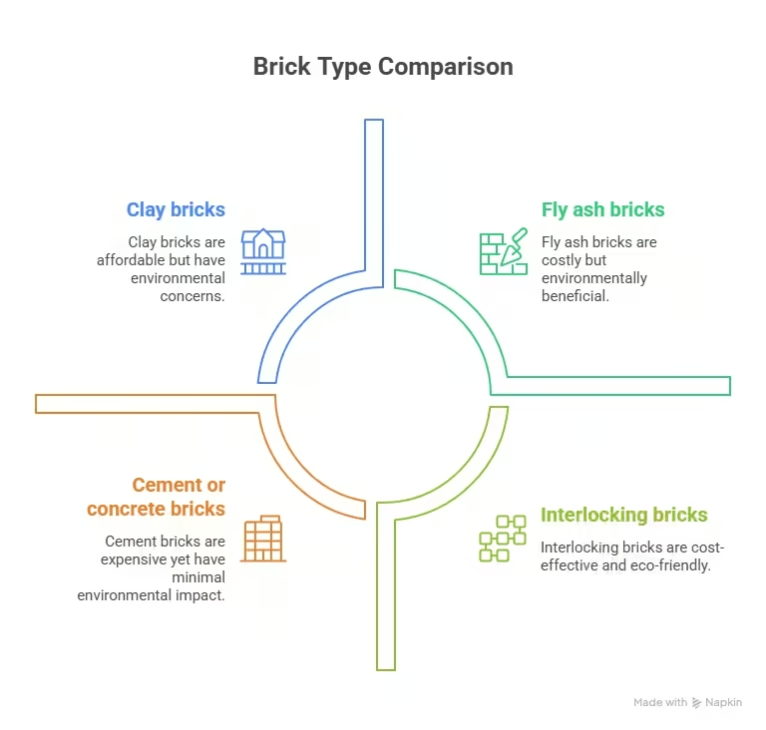

Types of Bricks to Manufacture

Before you start, decide which type of brick makes sense for your market and budget. Each kind has its unique benefits and serves different construction needs.

| Brick Type | Key Features | Best For | Cost Level |

|---|---|---|---|

| Clay Bricks | Traditional, red, strong | General construction | Low |

| Fly Ash Bricks | Lightweight, eco-friendly, durable | Urban projects | Medium |

| Cement/Concrete | Uniform, strong, weather-resistant | Commercial buildings | Medium |

| Hollow Bricks | Insulated, lightweight, easy to handle | Modern buildings | Medium-High |

| Interlocking Bricks | No need for mortar, quick to assemble | Fast builds, rural | High |

- Clay bricks are the classic choice—affordable and still widely used.

- Fly ash bricks are growing in popularity due to their environmental benefits and are great for larger construction projects.

- Cement or concrete bricks last long and have uniform dimensions, ideal for bigger commercial spaces.

- Hollow bricks reduce weight and provide natural insulation.

- Interlocking bricks save on labor and mortar, helping projects move faster.

Match your offering with what’s popular in your region and what builders are buying.

Choosing the Right Location for Your Brick Business

You don’t need a fancy shop to start a brick manufacturing business, but you do need the right plot. A workspace of 1,000 to 2,000 sq. ft. is the minimum. As you scale, more area helps with both production and logistics.

What to look for:

- Space for manufacturing, storing raw material, and inventory.

- Proximity to main roads for simple loading and delivery.

- Close to construction sites to cut down on delivery costs.

- Low rental prices to improve your bottom line.

Cost-effectiveness and convenience matter. If materials and finished bricks are easy to move in and out, your business flows better and costs stay down.

- Workspace size

- Road access

- Near suppliers and customers

- Affordable lease or purchase cost

Location can make or break your business—don’t rush this step.

Sourcing Raw Materials

Your brick quality starts with your raw materials. Depending on the type of brick, these ingredients can include soil, clay, lime, cement, and sand. Sourcing them locally is smart. It saves both money and time.

Checklist for Raw Material Sourcing:

- List all needed materials for your chosen brick type.

- Find local suppliers with consistent quality and fair prices.

- Set up backup suppliers to prevent production delays.

- Keep an eye on the cost and quality of materials.

Reliability is just as important as price. Running out of materials during peak season can cripple your operation. Review material costs often to keep your business profitable.

For a deeper dive into market analysis, licenses, manpower requirements, and common headaches, check out essential tips for starting a brick factory business for more practical insights.

Machinery and Equipment Setup

Old-school bricks were handmade, but now, machines do most of the work. This makes production faster and the quality more consistent.

- Mixers: Blend material for uniformity and quality.

- Molders: Shape the bricks.

- Dryers: Remove moisture for long-lasting bricks.

Prices for machines start at about ₹3 lakh (about $3,600) and rise with features, automation, and output. It’s worth comparing multiple suppliers for price, reliability, and after-sales support. A good warranty and helpful service can save you big headaches.

Essential Machine List:

- Brick clay mixing machine

- Molding machine

- Concrete block machine

- Drying/curing beds

- Kiln or electric dryer

- Weighing scale and molds

- Water pump

Tip: Look for suppliers offering both a warranty and good after-sales support so you’re not stranded if a machine breaks down.

For specialized machines:

- Find a hydraulic brick making machine

- Browse general brick making machines

- See options for a fly ash brick making machine

Cost Estimation for Starting the Business

Here’s what you can expect to spend to get a brick manufacturing business off the ground:

| Item | Estimated Cost |

|---|---|

| Raw materials | ₹2-3 lakh |

| Electricity, water, space | ₹2-3 lakh |

| Working capital (per day) | ₹25,000-30,000 |

| Total (medium scale setup) | ₹15-25 lakh |

| Large scale operations | ₹30 lakh+ |

Factor in periodic costs like repairs, marketing, and labor. If you start out medium-scale, you can always upgrade as demand grows.

If you want a more detailed cost breakdown or want to compare with other businesses, be sure to check the complete guide to starting a brick factory.

Licenses and Legal Requirements

You must have the proper licenses and permits before producing or selling a single brick. Getting your paperwork in order avoids fines and shutdowns later.

Licenses and Permits Checklist

- Register your business (choose your structure: sole proprietor, partnership, company).

- A trade license from your local authority.

- Environmental permits (especially if you run a kiln, as pollution laws apply).

- Land use permit and factory license (as per the Factories Act).

- Register for GST if your turnover exceeds government thresholds.

Consult a local legal advisor to ensure you’ve covered all bases, as state regulations might differ.

If you want a step-by-step overview of planning, permits, and more, the article on How to Write a Business Plan can guide you through laying a strong foundation.

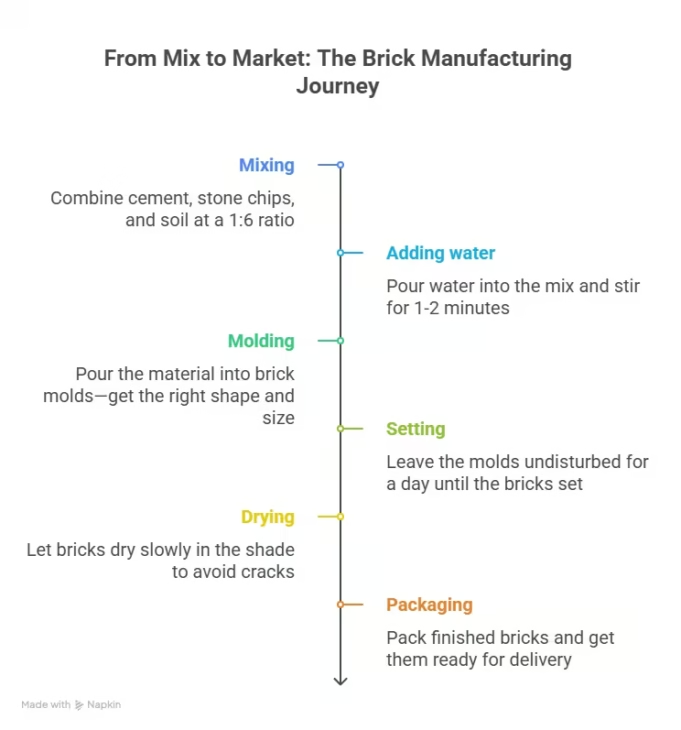

Overview of the Brick Manufacturing Process

For most new businesses, cement, fly ash, or concrete bricks are easiest to start with since machinery does most of the work.

Step-by-Step Production:

- Mixing: Combine cement, stone chips, and soil at a 1:6 ratio.

- Adding water: Pour water into the mix and stir for 1-2 minutes.

- Molding: Pour the material into brick molds—get the right shape and size.

- Setting: Leave the molds undisturbed for a day until the bricks set.

- Drying: Let bricks dry slowly in the shade to avoid cracks (machines can speed this process).

- Packaging: Pack finished bricks and get them ready for delivery.

Note: Drying is crucial. If you rush this step, bricks may shrink and crack, affecting both quality and resale value.

A slow, steady approach beats shortcuts every time.

For a broader look at manufacturing steps and quality checks, the blog on starting a brick making business highlights practical industry steps.

Marketing Strategies for Brick Business

Local construction companies, contractors, real estate developers, and hardware stores should be your first targets. They buy in bulk and need reliable suppliers.

Easy ways to market your bricks:

- Deliver on time and keep your promises to build your reputation. Happy customers will refer others.

- Use digital tools to stand out. Post short videos showing your manufacturing process or factory tours—transparency builds trust.

- Set up a WhatsApp Business profile. Share photos, prices, and delivery info easily.

- Post in construction-focused Facebook groups in your area.

- Offer discounts or flexible payment terms to attract regular clients.

Good marketing fuels growth. It can multiply orders and deepen community ties, turning a steady customer into a repeat partner.

Profitability and Expected Returns

Let’s run the numbers for a typical semi-automatic unit:

- Investment: ₹15–25 lakh

- Monthly production: Up to 1 lakh bricks

- Potential profit: ₹1.5–2 lakh per month (after expenses)

- Room for growth: Higher production = higher profits

Profits depend on what you produce, your costs, and your ability to sell in your chosen markets. Long-term contracts with construction companies give especially stable returns.

Summary:

- Investment: ₹15–25 lakh

- Output: 1 lakh bricks/month

- Net profit: ₹1.5–2 lakh/month

The key is efficiency—buy smart, produce reliably, and sell at the right price.

Additional Resources and Links

Looking for equipment? These platforms can get you started:

- See a wide range of hydraulic brick making machines

- Compare brick-making machines to suit your needs

- Explore fly ash brick making machines for eco-friendly options

Want more business ideas or see how others are starting? Check out playlists and tips shared directly in the video description for current tools and inspiration.

Conclusion

Launching a brick manufacturing business places you at the center of a growing, essential industry. With steady demand, manageable investment, and room for healthy profits, this business suits many first-time and experienced entrepreneurs alike. By focusing on quality, legal compliance, and strong local relationships, you can build a company that stands firm for years to come.

Have questions? Share your thoughts in the comments or reach out through the contact options listed on our resources. If you found this guide useful, share it with your network and keep exploring fresh ideas that work.

Ready to lay the foundation of your own business? Now is the time.

Nice blog